Wood has always been sensitive to changes in moisture content. If a change in moisture content occurs, shrinking, warping and other unsightly moisture problems can damage beautiful woodwork. Click for more info on shrinking and warping.

High Humidity: At 67% relative humidity and 75°F dry wood absorbs moisture to 12%.

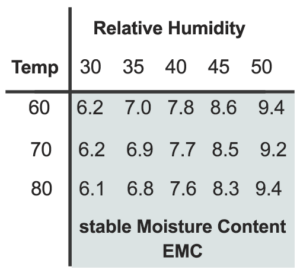

Wood will absorb or loose moisture until an equilibrium with the surrounding air has been reached. For each wood moisture content there is one specific relative humidity and temperature, when wood is stable and does not gain or lose any moisture. This moisture content is called an equilibrium moisture content.

Stable conditions for wood are reached, when the moisture content (MC) is the same as the equilibrium moisture content (EMC). Click here for EMC chart for relative humidity of 5%-95%.

Stable Condition: At 35% relative humidity and 70°F wood with 7%moisture content will not change.

Long-term, dimensional stability and beauty of woodwork is only guaranteed when wood moisture and relative humidity stay within close range of values listed in the EMC chart. As an example, you should never use airdried lumber to built furniture for inside your home, unless you checked first with a moisture meter that the wood is as dry as all the other furniture which has been in your home for a long time.

Once the EMC has been reached and relative humidity and ambient temperature are not changing, wood is dimensionally stable. No more shrinking or warping will occur – ideal conditions have been reached.

When wood absorbs and loses moisture below the Fiber Saturation Point (around 25-30%) wood swells or shrinks. To make matters worse shrinking and swelling is often accompanied by warping. Now, we have moisture problems.

See chapter: Shrinking, Warping and the Perfect Board.

Following are examples showing the difference in the equilibrium moisture content (EMC) between dry winters and moist summers:

At 70°F and 75% relative humidity, wood moisture will reach 14%.

At 70°F and 35% relative humidity, wood moisture will reach 7%.

At 70°F and 20% relative humidity, wood moisture will reach 4.5%.

If wood pieces with different moisture contents (some drier, some with more moisture) were placed in a constant climate of 70°F and 35% relative humidity, all pieces would end up with a moisture content of 7%, independent of wood species or initial moisture content. Since in-house conditions are usually between 30-50% relative humidity, the magic moisture content for stable woodwork, furniture and hardwood floors inside a building is 6-8%. See also EMC graph.

Moisture Problems are predictable: Compare wood moisture, relative humidity and ambient temperature with the EMC Chart to find out if wood will absorb moisture, keep its moisture content or loose moisture and shrink:

+

Prevent Moisture Problems

Compare wood moisture, relative humidity and ambient temperature with the EMC Chart to find out if wood will absorb moisture, keep its moisture content or loose moisture and shrink:

– Use a moisture meter to determine the wood moisture content.

– Use a Thermo-Hygrometer to measure relative humidity.

– Use the EMC Table to find the corresponding EMC for the

relative humidity of the surrounding air.

No shrinking or warping will occur when wood moisture and EMC of the surrounding air are the same. Wood is stable.

Click here for complete EMC Table

More EMC values and the corresponding relative humidity and temperature values can be found on the Internet at:

www.EMCCalculator.com

Click here for more info on Lignomat Pin Meters

Lignomat pin meters can measure all thicknesses from veneer to lumber to logs, from wet to dry, from flat boards to round or oddly shaped pieces. Lignomat mini-Ligno series have7 different pocket-size models with built-in pins to meet your needs for moisture range, materials to be measured, number of wood group corrections and budget. We offer electrodes (hand probes) with insulated pins for wood and other materials. They can be connected to extension cables for in-kiln moisture monitoring, for restoration jobs or for building surveillance. Ligno-VersaTec and Lignometer K moisture meters come with the widest measuring range, individualized wood species corrections, wood temperature corrections and calibrations for non-wood materials. The LCD display shows the measured moisture value with 0.1% resolution for the entire range and indicates wood species and wood temperature settings.

Click here for more info on Lignomat Pinless Meters

Lignomat pinless meters are ideal for measuring boards, panels and floor planks as well as scanning for moisture problems in floors, walls and ceilings. Large areas can be scanned quickly, and no effort is needed to insert pins into hard wood. No pin holes are left, which is crucial when measuring finished products and wood floors. If measuring low moisture contents is part of the scope of the moisture meter, Lignomat’s pinless moisture meters measure lower moisture contents in hardwood than pin moisture meters. There are also limitations of pinless meters that a flat surface is needed. Pinless moisture meters work on rough sawn or scrapped wood, however round and oddly shaped pieces cannot be measured accurately.

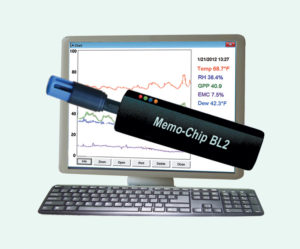

Click here for more info on BL2

The new BL2 – an RH/EMC data logger from Lignomat – measures relative humidity and ambient temperature and indicates the EMC. They are on-site with cables or wireless with remote access. You can even set an EMC alarm which alerts when the EMC is exceeding or falling under preset limits.

The BL2 is a watchdog alarm for relative humidity and moisture in all types of buildings and flooring applications.